INR 4000002 INR 4200000

You Save 4.76%

INR 2000000 INR 2200000

You Save 9.09%

INR 140000 INR 150000

You Save 6.67%

INR 40000 INR 50000

You Save 20%

INR 20000 INR 30000

You Save 33.33%

INR 12000 INR 20000

You Save 40%

INR 120000 INR 140000

You Save 14.29%

INR 12000 INR 20000

You Save 40%

INR 20000 INR 30000

You Save 33.33%

INR 1500000

INR 250000

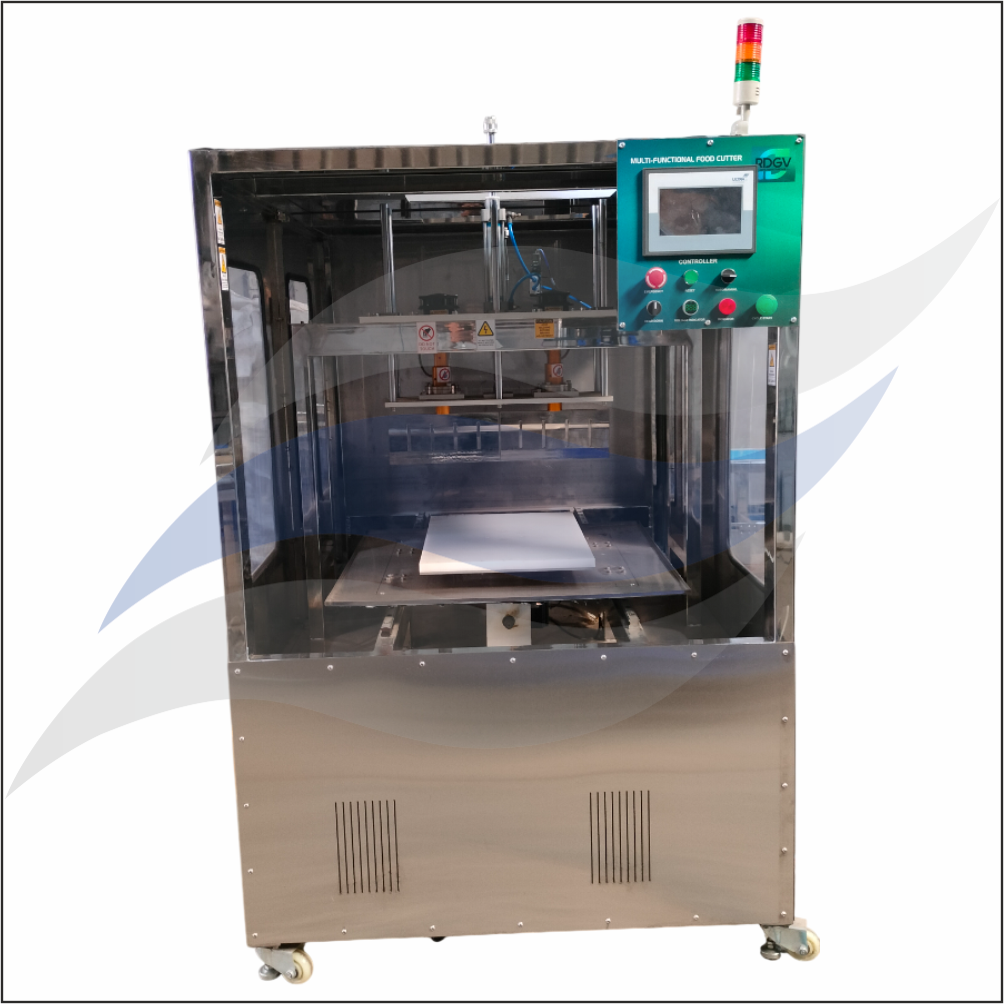

No greasing oil required |Maintenance |No assembly voices |High strength between welded portions |Speed |Reliability |Safety |Flexibility |Dynamic Force & Amplitude Control with Multi-Ste |High durability |Capability of unique force and amplitude parameter |Easy To Operate |Single Spot |Double Spot |ultrasonic vibration |Ultrasonic |transducers |piezoelectric element contracts |frequency of the ultrasonic waves |ultrasonic food cutting |Affordable Food Cutting Machine |Best Cutting Machine |Food Cutting Machine |Ultrasonic Food Cutting Machine |Best Food Cutting Machine |Paneer Cutting Machine |Pizza Cutting Machine |Cake Cutting Machine |Meat Cutting Machhine |Bakarwadi Cutting Machine |foodcutter |ultrasonicfoodcutter |cakecutter |foodcuttingmachine |ultrasonicprobesonicator |Probe Sonicator |probe |homogenizer |ultrasonicator |Plastic Welding Hand Gun |plasticweldingmachine |ppcorrugatedboxwelding |ppcorrugatedboxweldinghandgun