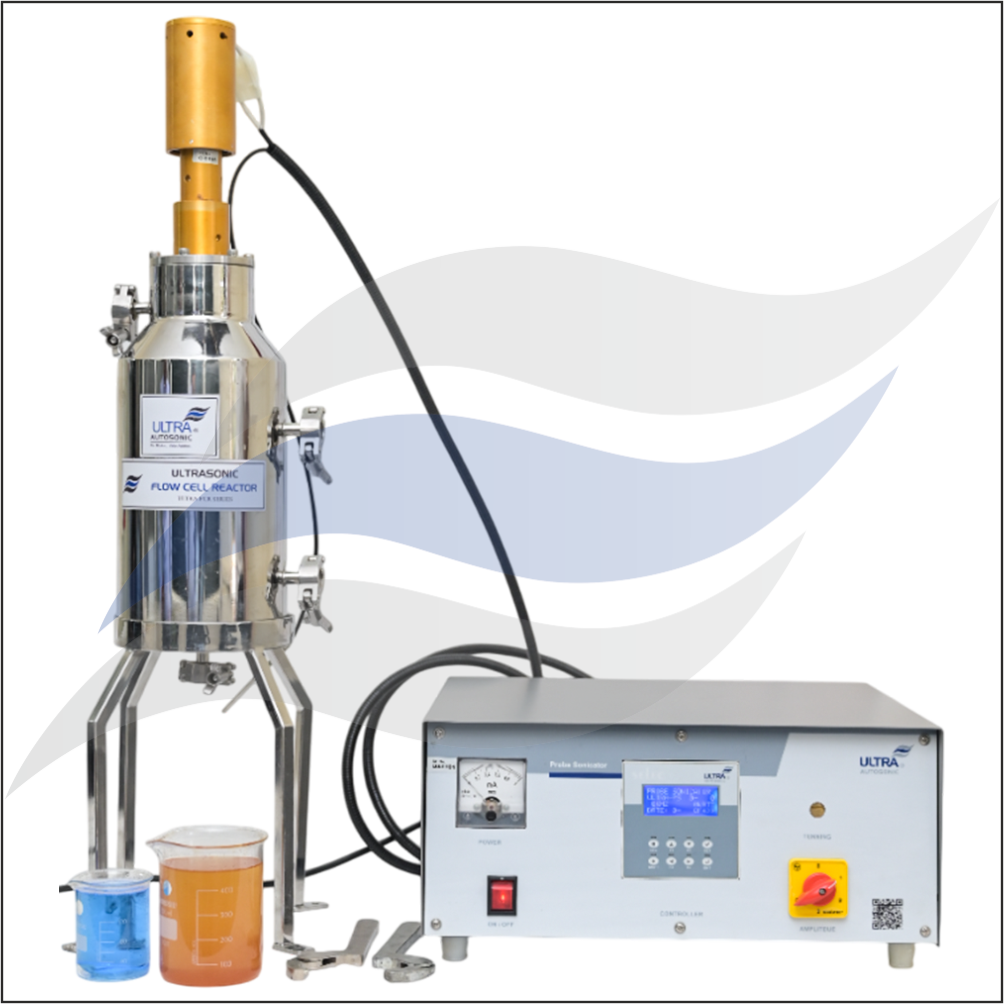

INR 550000

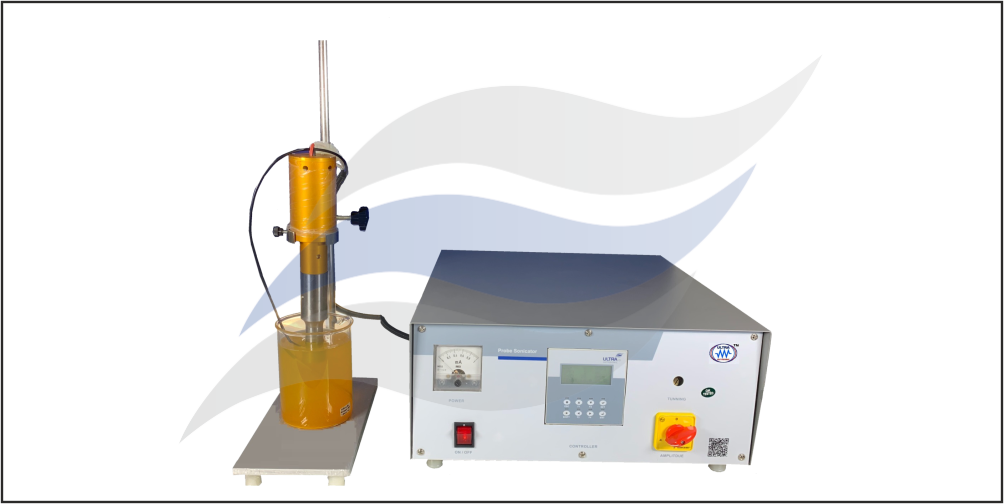

INR 250000

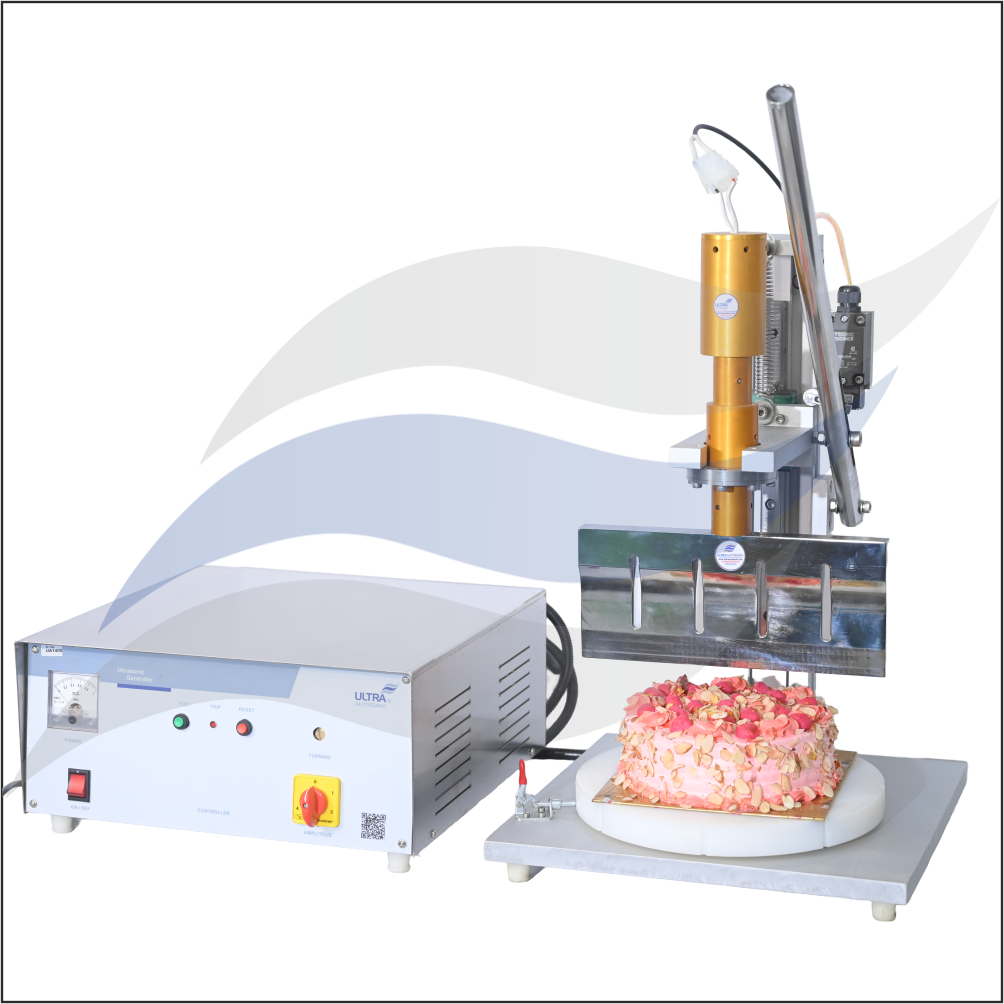

INR 1500000

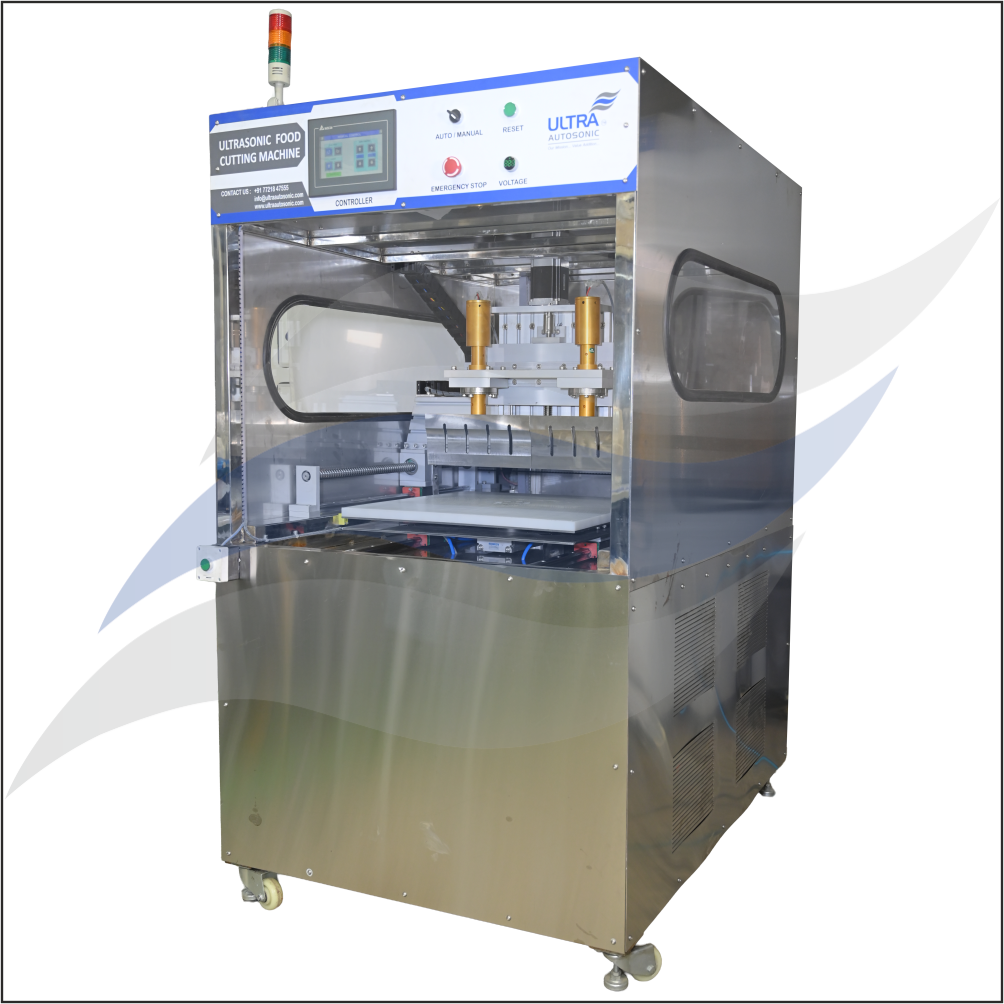

INR 9000000

INR 850000 INR 860000

You Save 1.16%

INR 150000 INR 170000

You Save 11.76%

INR 225000 INR 250000

You Save 10%

INR 255000 INR 275000

You Save 7.27%

INR 725000 INR 750000

You Save 3.33%

INR 250000 INR 275000

You Save 9.09%

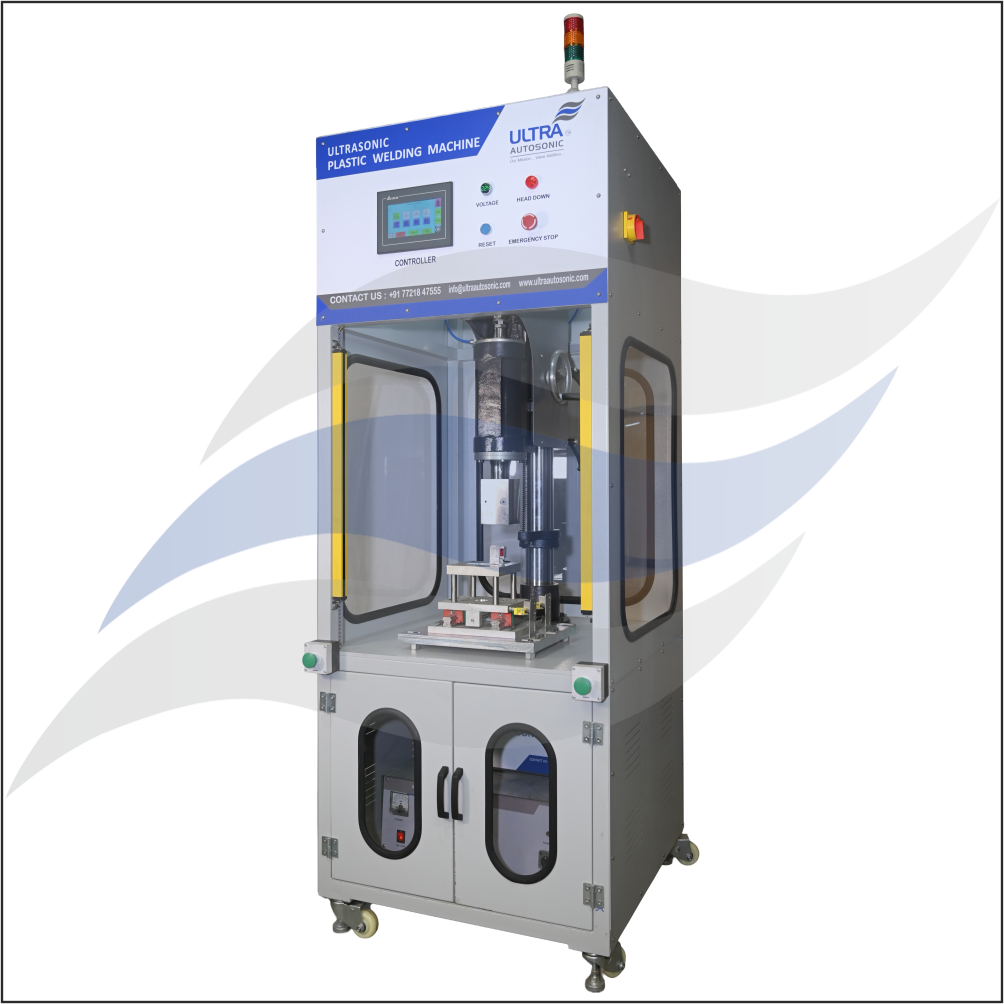

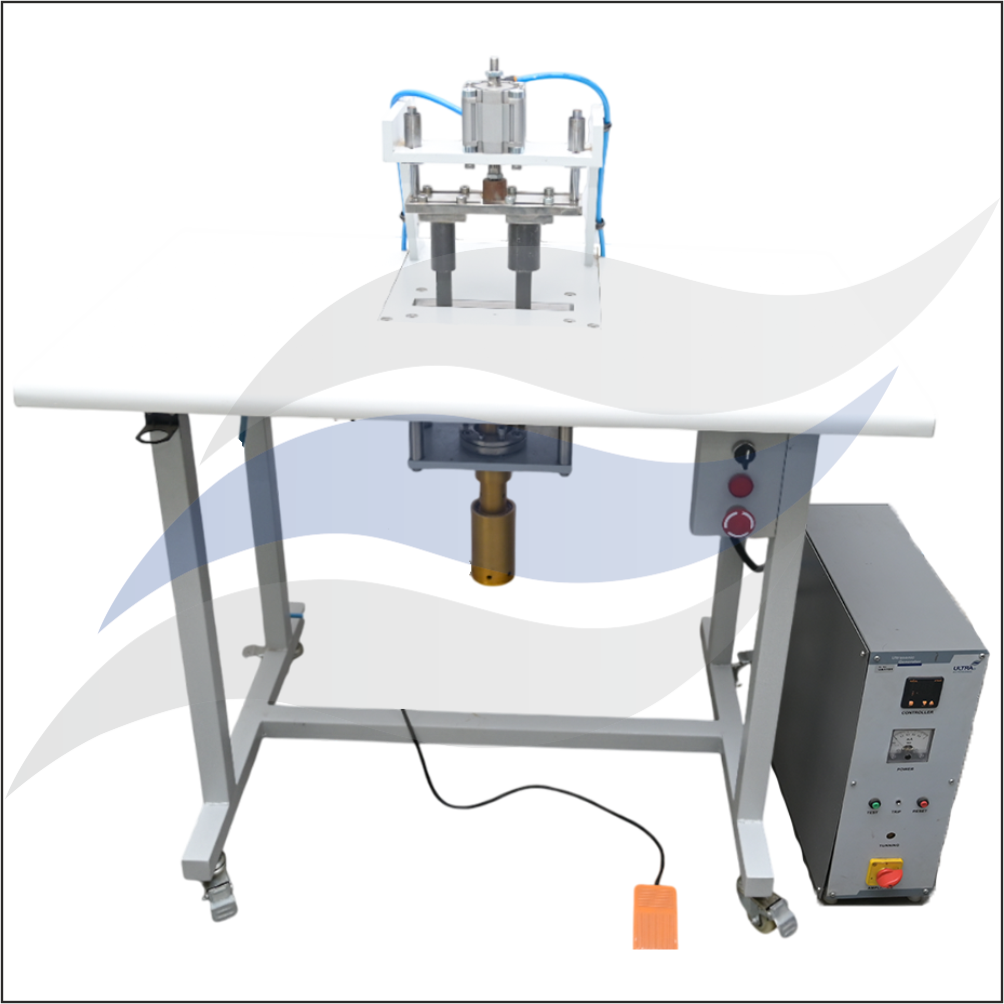

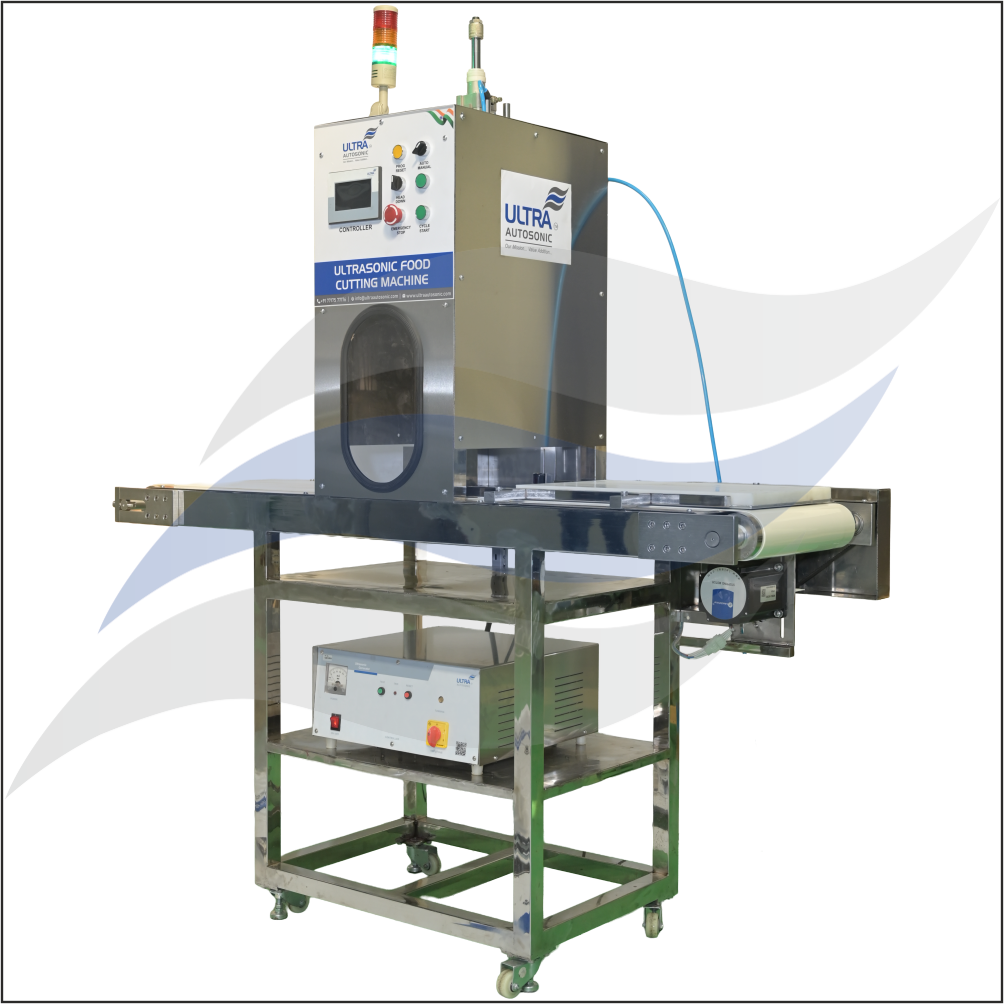

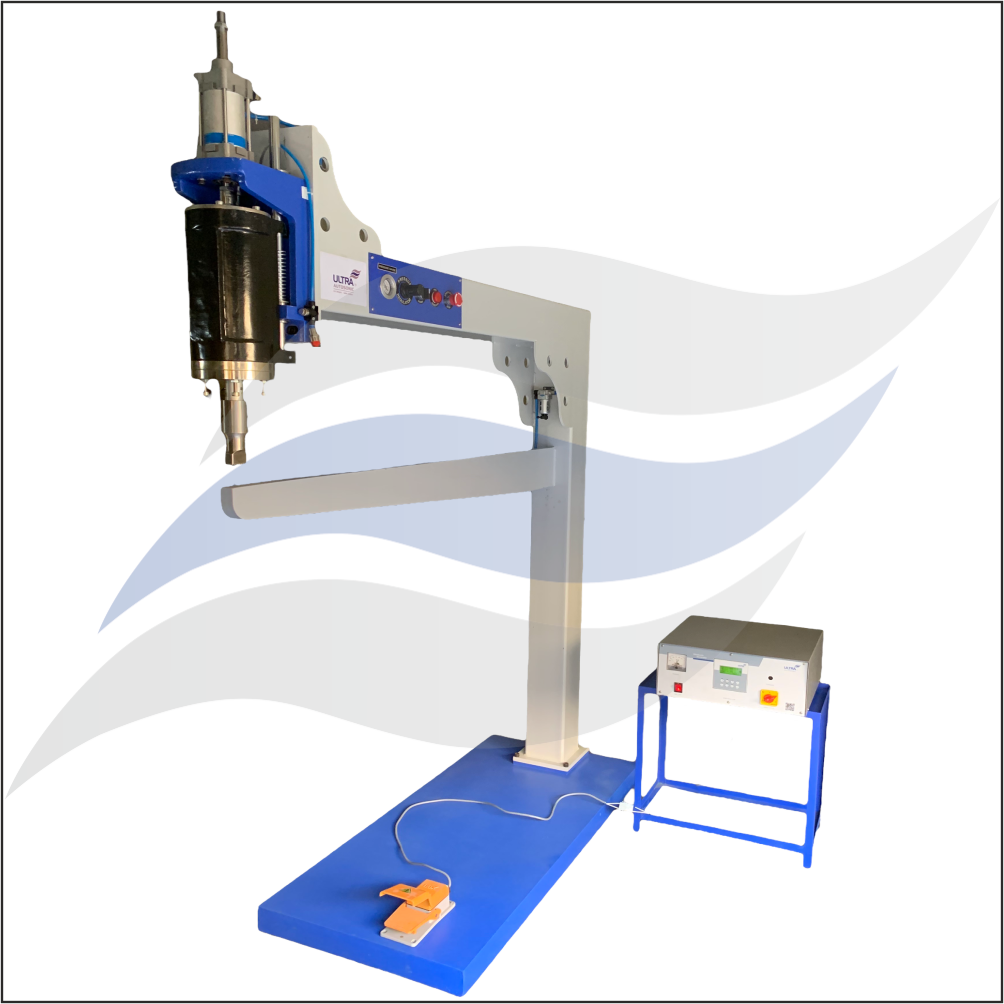

No greasing oil required |Maintenance |No assembly voices |High strength between welded portions |Speed |Reliability |Safety |Flexibility |Dynamic Force & Amplitude Control with Multi-Ste |High durability |Capability of unique force and amplitude parameter |Easy To Operate |Single Spot |Double Spot |ultrasonic vibration |Ultrasonic |transducers |piezoelectric element contracts |frequency of the ultrasonic waves |ultrasonic food cutting |Affordable Food Cutting Machine |Best Cutting Machine |Food Cutting Machine |Ultrasonic Food Cutting Machine |Best Food Cutting Machine |Paneer Cutting Machine |Pizza Cutting Machine |Cake Cutting Machine |Meat Cutting Machhine |Bakarwadi Cutting Machine |foodcutter |ultrasonicfoodcutter |cakecutter |foodcuttingmachine |ultrasonicprobesonicator |Probe Sonicator |probe |homogenizer |ultrasonicator |Plastic Welding Hand Gun |plasticweldingmachine |ppcorrugatedboxwelding |ppcorrugatedboxweldinghandgun