Description

Product details

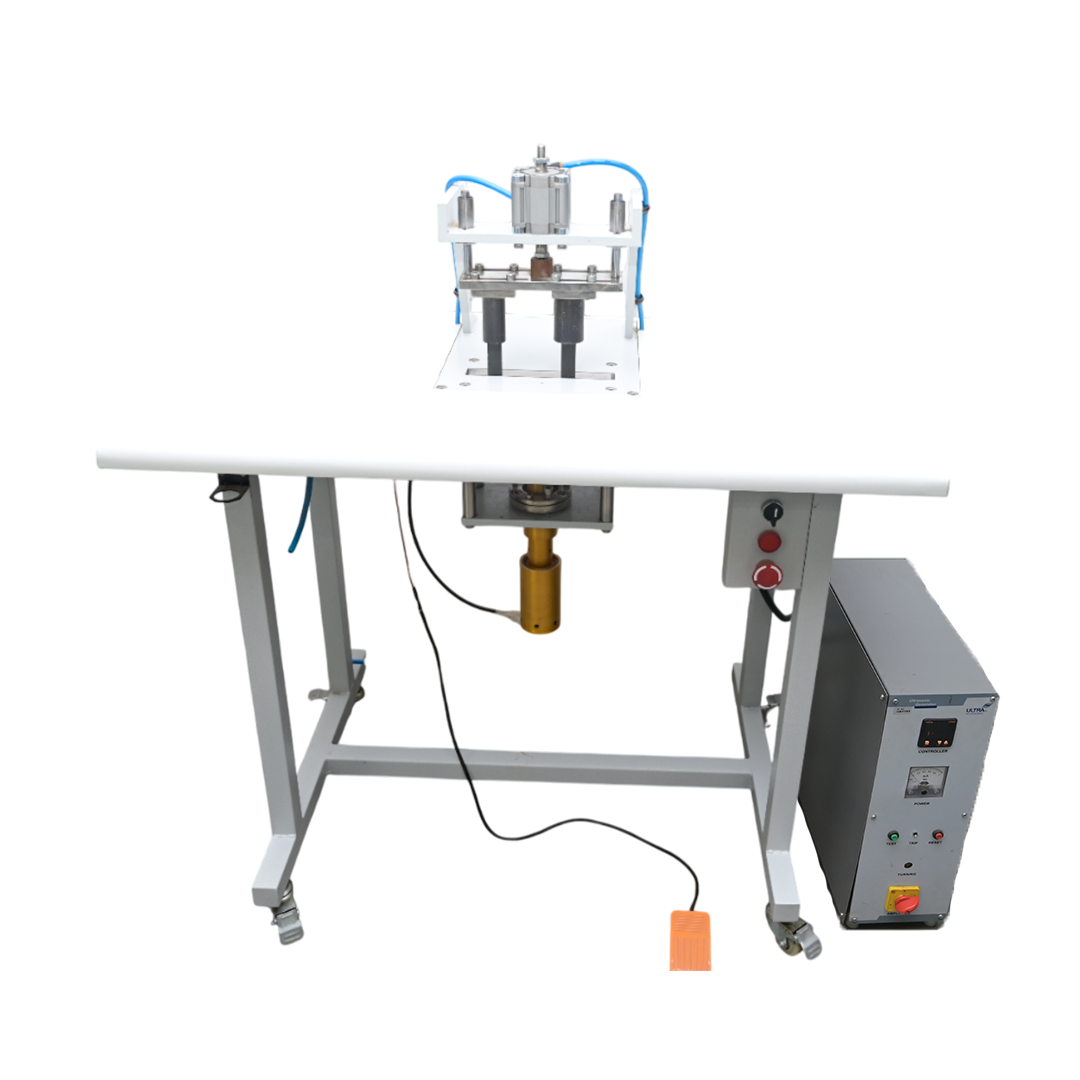

Ultrasonic Plastic Welding is a process of joining thermoplastic materials by applying high-frequency acoustic vibrations to the parts being joined. An ultrasonic plastic welding machine typically consists of a power supply, a transducer, a welding horn, and a fixture or tooling. Ultrasonic plastic welding is commonly used in industries such as automotive, medical, packaging, electrical, and consumer goods for joining parts such as housings, panels, filters, and components. It offers several advantages over other welding methods, including fast cycle times, high strength and hermetic seals, and the ability to weld complex geometries and dissimilar materials. MODEL-ULTRA UPWM Series ULTRA UPWM 15- 2600 ULTRA UPWM 20-1000 ULTRA UPWM 20-1200 ULTRA UPWM 20-1500 ULTRA UPWM 20-1800 ULTRA UPWM 20-2000 Actual Weight-Approx. 96 kg Actual Size (L x W x H) -Approx. (728 X 434 X 1193) mm Packaging Type-Wooden Box Working Pressure-2 to 10 bars (Air Compressor required 1Hp 50Ltr) Applications Bumpers, Air Filters, Car Audio, Foot Pads, Door Panels. Chargers, Storage Battery, Mobile Panels, Telephones, Sockets, Humidifiers. Photo Albums, Folder Files, Name Card Holders, Ink Bottles Cap. Joining Of Two Different Plastic Parts, Assembly Of Plastic Toys. Air Cooler Parts Welding & Velcro Welding. I-card Lace Welding & Impeller & Impeller Bowl Welding.